SMEs are a critical engine of SA’s economy. They represent more than 98% of businesses, according to consultancy McKinsey & Co, and employ 50% to 60% of the country’s workforce across all sectors. They are also responsible for 25% of private-sector job growth. But they are buckling under the weight of rising operating costs – energy prices in particular.

The energy bill is certainly a significant cost factor for SMEs, but what compounds this further, says Mike Anderson, founder and CEO of the National Small Business Chamber, is the lack of energy available, which results in downtime and poor productivity. ‘In our recent surveys, this is one of the priority areas for most SMEs,’ he says. Indeed, power outages have a major impact on businesses – regardless of their size. In one of its latest energy reports, the CSIR notes that SA will endure an energy shortage for at least the next 18 months.

Considering the current economic climate, pandemic and load shedding, Anderson says there needs to be constant education and specific key tips on what every business can do to reduce its energy costs. ‘There is an enormous opportunity to provide national educational initiatives,’ he adds. In the main, he says, ‘SMEs are ill-informed with regard to increasing energy efficiencies. This must be a collective responsibility between big business and government. SMEs need all the help they can get’.

While this lack of knowledge poses one problem, the inability of many SMEs to apply, at a practical level, anything that has been learnt poses another. ‘The problem within a number of SMEs is twofold,’ according to says Sashay Ramdharee, regional project manager of energy-systems optimisation at the National Cleaner Production Centre of South Africa (NCPC-SA). ‘Firstly, the issue of knowledge, and secondly, resources for implementation of the project.’

Ramdharee says that very early on the NCPC identified that it can use the best skills to compile a technically sound report but that if it presents this to companies where the ideas and concepts are not understood by the individuals, they risk implementation altogether. ‘We therefore introduced a number of training courses that cover the significant energy-use areas and energy-management system implementation. This allows for the critical transfer of skills through training, which in turn relates to implementation at sites.’

Barry Bredenkamp, GM of energy efficiency at the South African National Energy Development Institute, says there is a tendency to become ‘bogged down’ in the technicalities associated with energy-efficiency interventions. ‘While these are certainly important, we need to revert back to the basics of energy efficiency, such as straightforward retrofit technologies like cool roofs, insulation and lighting retrofits, behaviour change and basic energy auditing,’ he says. ‘Addressing this would require more online and affordable training for SMEs, which should include practical project opportunities.’

To improve their energy efficiency, Bredenkamp argues that SMEs need a mix of access to affordable skills, awareness of technologies that are rapidly evolving, and funding. ‘The main issue is access to products and services, which can include finance,’ he says.

Conducting an energy audit is a good place for any company to start. This analyses a site’s energy usage and costs, checks the business’ energy tariffs to ensure it is not being overcharged, looks for energy wastage, and identifies options to save both energy and money. The Green Building Council of South Africa has a very useful measure, called the energy and water benchmarking tool, which can be used to evaluate how a building is performing in terms of energy and water.

Alison Groves, regional director of building services at WSP Africa, says it is important for a business to understand what its energy needs are; what uses the most energy; and who is responsible for that use.

‘Measure your energy – if necessary, put in meters,’ she says. ‘Keep records of your consumption, as detailed as possible. You never know what patterns may emerge from the data. Do the same with water – measure and record it. I would recommend doing it on a spreadsheet. That way you can generate graphs to help visualise the information.’

Ramdharee agrees. ‘Data is of critical importance. You can’t effectively control what is not metered,’ he says. ‘We urge companies to log their [energy consumption and production] data, which can allow for baseline development prior to implementation of energy-savings projects.’ This has a tremendous benefit in tracking and identifying the savings that have been achieved by implementation of energy-efficiency interventions, he explains.

When it comes to better in-house energy management, Ramdharee says simply identifying and switching off unnecessary loads or those not in use can make a marked difference to an SME’s bottom line. A focus on behaviour change and operational control projects is also worthwhile, he says, as these projects are predominantly low to no-cost initiatives, and thus there is no time delay in implementation, leading to immediate savings.

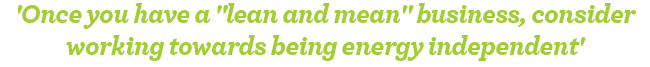

Groves further suggests that businesses observe and understand how people behave in their work space, as well as how equipment is used. This will help identify any efficiencies that can be achieved by changing people’s behaviour. Businesses can then consider upgrading to more efficient equipment. ‘Once you have a “lean and mean” business, consider working towards being energy independent,’ she says. ‘With Eskom raising electricity prices, as well as changing the structure of peak-energy pricing, this may be an expensive initial cost but will help save in the long run.’

While Bredenkamp recommends that SMEs transition to renewable-energy technologies, he adds they should not aim to achieve this overnight. Rather, they should compile a step-by-step plan with an ‘off-grid end-state’ in mind, gradually investing in each of the appropriate technologies and using the savings from one intervention to finance the next. The ‘golden rule’, he says, is to become as energy efficient as possible before investing in renewable technologies, as that will reduce the size – and, ultimately, the cost – of the renewable-energy technologies required.

‘What is also significant and of benefit to SMEs is the whole transition to what is commonly referred to as the “digitalised economy” – where devices are interconnected, leading to optimal use of resources and the saving of money,’ adds Bredenkamp. He cites the current trend of attending online meetings as opposed to driving to and from venues, spending money on fuel, sitting in traffic and so on as an example of this.

In Ramdharee’s experience, ‘SA industry is largely unaware of the tremendous potential that exists within their facilities for “small project” energy-efficiency savings. Training and awareness to assist with realisation or identification of the opportunity that exists is the biggest hurdle, as you cannot implement and save when you do not know about the opportunity that exists. The implementation of numerous “low-hanging fruit” projects culminates in a large saving, and this is a trend we’ve noticed across many companies we worked with, representing approximately 70% of the savings achieved in the project’.

One of the NCPC’s current energy-efficiency initiatives is the South African Industrial Energy Efficiency (IEE) project, which was launched in 2010 to assist industrial companies around SA to save energy and money, improve effectiveness, and demonstrate the positive impact of energy management on GHG emissions. Through implementation support and internationally recognised training, the IEE project assists companies to realise energy, GHG and financial savings though in-plant energy management. ‘Now in its second phase, the IEE project is a multi-stakeholder initiative that supports increased and sustained energy efficiency within industrial and selected commercial sectors by promoting the increased adoption of energy-management systems, energy systems optimisation and the ISO 50001 series,’ says Ramdharee.

The numbers certainly demonstrate the effectiveness, with 4.286 GWh of cumulative energy saved between 2011 and 2019, just shy of 4 million tons of CO2 mitigated for the same period, and cumulative financial savings of R3.3 billion.

If businesses needed further convincing, there are also tax breaks to be enjoyed. The Section 12L energy-efficiency tax incentive provides an allowance for businesses to implement energy-efficiency savings and claim a tax deduction of 95c/kWh saved on energy consumption. According to Bredenkamp, an increased number of 12L tax incentive applications have been received over the past year. He says the uptake of this incentive is a positive trend. ‘It really shows government’s commitment to decarbonising South Africa’s industrial and commercial industries.’

The country’s carbon tax came into effect in 2019 – after almost a decade of discussion – and seems to have provided the impetus that industry needed.

‘Companies are finally understanding that there is real money involved here, not to mention the environmental aspects,’ says Bredenkamp. ‘If we can continue to provide financial incentives for cleaner practices, perhaps we can go to COP26 in Scotland in November 2021 with some good news on our journey towards a less carbon-intensive economy in South Africa.’

Groves notes that while national government and municipalities are making marked inroads in developing policy to encourage more sustainable use of our resources, the implementation of these policies is slow. Moreover, businesses are reluctant to adopt sustainability ahead of their competition because of the belief that it is expensive and that they would become uncompetitive. The advantages of energy and water efficiency will, however, provide long-term economic sustainability to businesses that are facing great difficulties in this constrained economy.

‘In normal times, it’s tough for the SME sector,’ says Anderson. ‘Outside of a pandemic, load shedding and an economic downturn, only one out of 12 businesses that start will survive. These horrific statistics have worsened over the past year.’ He adds that despite this, business owners and entrepreneurs within the SME sector are largely positive and resilient. However, ‘big business’ and government must do whatever is needed to sustain the growth and sustainability of this all-important sector.

‘The SME sector is the mainstay of our economy and the engine of our society,’ says Anderson. ‘It is the future of job creation and the only solution for unemployment.’