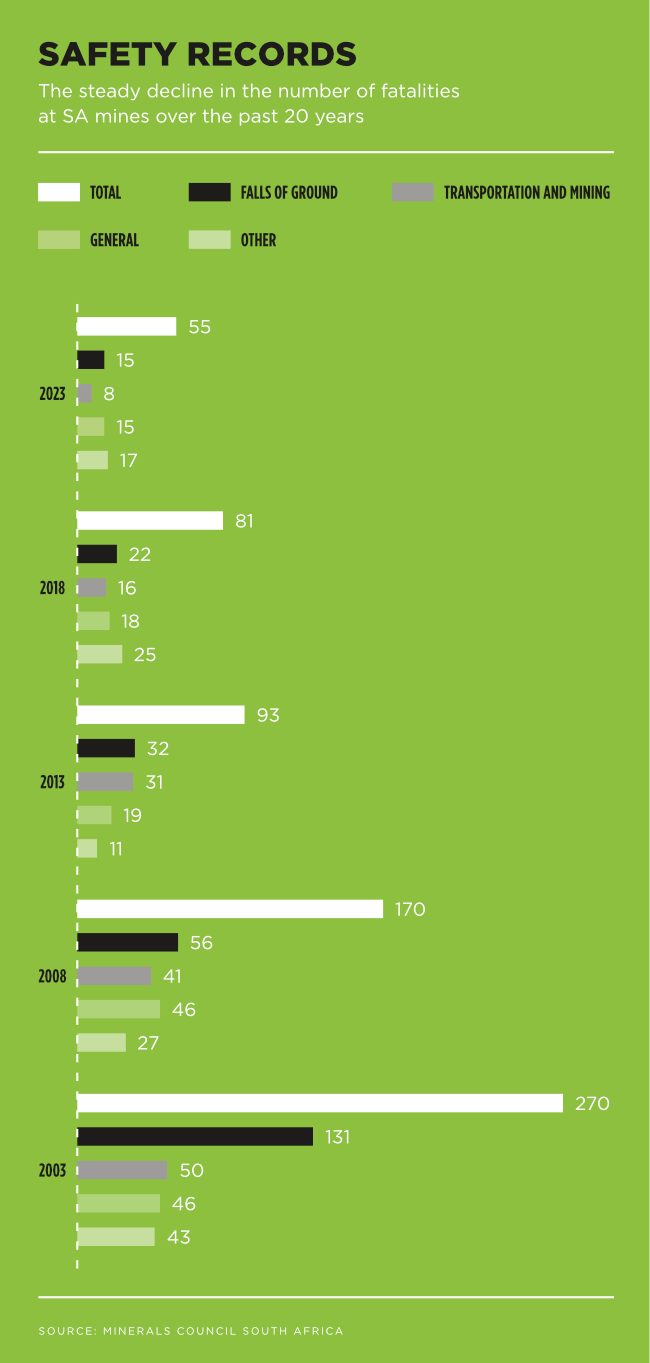

In late 2023, the issue of mineworker safety was thrust into national prominence when an incident at Implats’ 11 Shaft in Rustenburg saw 12 mineworkers lose their lives, with another 75 injured. More than a year later, there is little additional official public information on the underlying causes for this anomaly in what has been a trajectory of consistent and unprecedented improvement in mining safety in SA mines. In 2022, there was a 34% reduction in fatalities from the preceding year (from 74 deaths to 49) – the lowest number of annual fatalities in the industry’s recorded history.

This trend was on track to continue into 2023, until the incident at Implats, bringing total fatalities in 2023 to 55. In 2024, the mining industry had reported 36 fatalities by early December. These gains are in large part due to measures put in place by the Minerals Council South Africa (MCSA).

‘In 2011, the Minerals Council initiated CEO-level discussions on health and safety, which are now institutionalised as the CEO Zero Harm Forum,’ says Dushendra Naidoo, head of safety and sustainable development at the MCSA. ‘This forum meets quarterly to review and advise on our performance regarding health and safety.’

The MCSA’s board has initiated a monthly Safety Hour of Learning where recent incidents are shared with the sole purpose of learning from each other and preventing similar incidents in the future.

‘We augmented our CEO-led initiatives in 2019 by adopting the Khumbul’ekhaya Health and Safety Strategy, which is […] a rallying cry for step-change efforts on health and safety,’ says Naidoo. ‘We are in the process of gathering CEO and other industry inputs on what has worked and what has been less effective as we develop our second iteration of the Khumbul’ekhaya strategy for implementation in 2025.’

Through the tripartite Mine Health and Safety Council, the MCSA jointly agreed on its first occupational health and safety milestones in 2003, followed by a second iteration in 2014 and the third in 2024. In that time, the industry has made significant strides. Since 2014, the incidence of occupational disease in the mining industry has decreased by 72%, and the number of fatalities related to safety incidents has declined by 35% between 2014 and 2023.

The achievement is even greater if we zoom out further. Since 1994, the number of fatalities on mines has decreased by 88%, from 484 to 55 in 2023. Injuries have decreased by 75% in that period.

The industry is paying particular attention to the key areas that have historically contributed the largest numbers of fatalities and accidents, according to Naidoo. ‘For example, the Fall of Ground Action Plan [FOGAP] has contributed to the number of [related] fatalities significantly reducing by 97.5% [from 239 in 1994 to six in 2022], a true indication that the FOGAP is working.

‘Our focus on transport and machinery incidents has resulted in fatalities from this agency decreasing by 91%, to eight from 87 three decades ago. We have also made significant inroads in reducing cases of silicosis and noise-induced hearing loss, with reductions of 90% and 86% respectively between 2003 and 2022. In addressing TB, the industry has gone from being a hotspot for the disease to well below the national average.’

SA is home to some of the deepest and most geologically complex mining operations in the world, which pose heightened risks of seismic events, rockfalls and ground instability. These conditions require advanced rock engineering and innovative safety approaches.

Perhaps for this reason, SA mining companies are recognised internationally for leading-edge developments in harm-reduction initiatives, including proximity detection systems, collision prevention systems and seismic monitoring technologies. These tools are often necessitated by the unique challenges of SA geology, which demands high levels of expertise in rock engineering and dynamic risk management.

‘A lot of world-leading research is being undertaken in South Africa through research centres and via FOGAP,’ says Naidoo.

These positive developments make the tragedy at Implats’ 11 Shaft all the more baffling. Where does the investigation currently stand? The in loco inspection into the incident was conducted in December 2023, following which Implats proceeded with further investigations and began the necessary repairs to the damaged infrastructure.

‘In January 2024, Impala submitted its investigation report to the DMPR [Department of Mineral and Petroleum Resources], required in terms of Section 11(5)(e) of the Mine Health and Safety Act, which paves the way for the DMPR to initiate formal proceedings relating to the incident,’ says Patrick Morutlwa, COO of Implats. ‘In parallel, Implats conducted its own investigations, drawing on observations and findings from the regulated investigation, and exploring potential interventions to further enhance the safe operation of all conveyance systems across the group.

‘This investigation, which was governed by internal, industry and regulatory protocols and procedures, was concluded and reviewed by a third party. The DMPR inquiry into the accident is scheduled to start in December 2024 and continue in 2025, until concluded. After the conclusion of that process, the learnings from the accident will be made available to the industry.’

It’s worth noting that Implats’ safety and operational risk strategy compares favourably with other leading mine companies. An eight-step tactical plan was developed to speed up embedding additional fatal risk-prevention controls in the operating culture at sites, with a focus on areas such as methodology and quality of planning, enhancing start-of-shift entry examinations, capacitating managers and supervisors, and addressing the high turnover in these roles; as well as an increased focus on the critical safe behaviours for each role, particularly those in high-risk work areas.

Along with other members of the MCSA, Sibanye-Stillwater submits its safety statistics to the Southern African Institute of Mining and Metallurgy (SAIMM), which then compares the annual performance and any improvement levels. Sibanye-Stillwater’s safety initiatives were recently recognised with six industry health and safety awards at the SAIMM MineSafe 2024 conference.

‘Sibanye-Stillwater continues to embed and operationalise safety practices with the primary focus on reducing high-potential risk areas guided by leading practices that inform group minimum safety standards,’ says James Wellsted, the company’s executive VP of investor relations and corporate affairs. ‘[Our awards] can be attributed to our comprehensive safety strategy and consistent implementation. Our approach includes rigorous safety protocols, continuous training and a strong focus on risk management. We continue to focus on the importance of value-based decision-making as part of our safety culture across all levels of the organisation.’

According to Wellsted, the company’s Fatal Elimination Strategy has been key to its continued progress in reducing serious injuries and fatalities. ‘We empower our employees and expect them to be accountable and take ownership of their safety and the safety of their colleagues.’ The increase in frontline stoppages – where workers have the right and responsibility to halt work immediately when they identify an unsafe condition or potential hazard that could compromise worker safety – is a positive sign that employees are increasingly assuming responsibility for withdrawing from unsafe work environments, and are confident enough to report near-miss incidents without fear of reprisal, he says.

‘We conduct regular safety audits and inspections to identify and mitigate potential hazards,’ adds Wellsted. ‘We have focused on continuous improvement through regular safety training and education for all employees and contractors. This includes comprehensive training on safety procedures and protocols, as well as ongoing safety awareness training. Our Learn From Incidents (LFI) reports have been instrumental in sharing safety learnings across our global operations.’

Ongoing challenges identified by MCSA include outdated systems and infrastructure that are not aligned with modern safety practices. Ensuring contractors adhere to the same stringent safety standards as mining companies is another persistent problem, as is cost. Balancing safety investments with budget pressures can generally lead to under-investment in advanced safety technologies.

As it stands, the industry is well aware of these weak spots and is actively working to address them, particularly in light of the events of November 2023.

‘When comparing the South African mining industry to its global counterparts, it is evident that significant progress has been made in reducing the fatality frequency rate since the early 2010s,’ says Naidoo. ‘Over the past five years, the South African industry has achieved performance levels comparable to those of Canada and Australia, while exceeding those of the United States.

‘This improvement is particularly noteworthy given that, in the mid-2000s, the industry’s safety performance lagged significantly, with fatality rates four times higher than those of these leading mining nations.

‘A closer examination of disaggregated statistics for the global coal sector reveals even more encouraging results. In 2022, the South African coal sector achieved the lowest fatality frequency rate among leading mining nations, recording an impressive rate of 0.03.’